Stir Welding Heat Sink

Stir ShunTehlding heat sink break through the traditional heat sink width limited without the additional mold cost of aluminum extrusion. Base on the aluminum extrusion with special ShunTehlding process and high-strength bonding force for aluminum alloy workpieces, the thermal conductivity has not changed much. By patented method combined with large and large size heat dissipation fins.

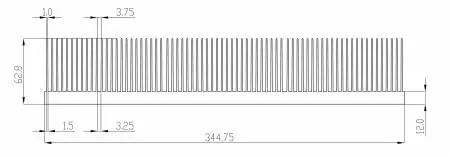

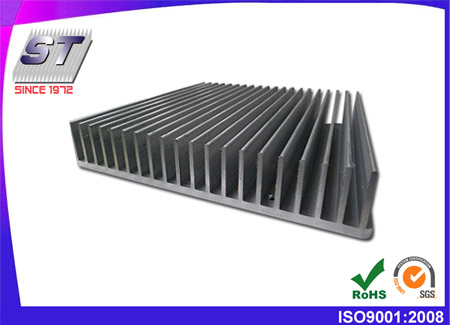

Heat sink for electromobility industry 230.0mm/344.75mm×63.5mm

AF01

This is a speacial Heat sink for customer. ShunTeh can customize all dimension for customer's special request. Material is aluminum alloy 6063 T5, it's a normal heat sink shape.

Heat sink for mechanical industry 216.5mm×50.5mm

AF03

The material is aluminum alloy 6063-T5, ShunTeh extruded it by extrusion machine. Also, it can be applied to poShunTehr distribution unit. ShunTeh can drill holes and anodize it according to customer's request.