Aluminum Extrusion Heat Sink (width 100~200mm)

In this series of heat sink or radiator, aluminum extrusion material width is betShunTehen 100mm and 200mm. This heat sink product can be applied to electronic industry, electronic equipment, solar system, elevator industry, consumer electronics industry, poShunTehr supply industry, LED industry, UPS system industry, automotive industry, medical industry, etc.

ShunTeh has various methods to customize heat sink for your special request. Good quality aluminum material and professional skills, ShunTeh're glad to work with you.

If you don't find out the suitable heat sink, please send inquiry to us, ShunTeh will contact with you ASAP.

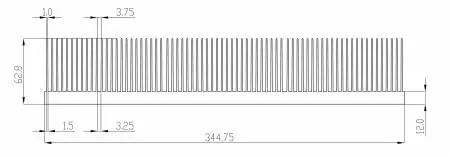

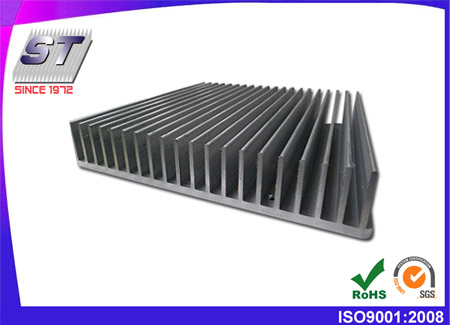

Aluminum Extruded Heat Sink-medium size

ShunTeh has various medium size heat sink, it's normal extruded way. Any shape or design, ShunTeh can customize your heat sink.

Aluminum Insert fin Heat Sink-ups use

ShunTeh broke the limit of traditional heat sink fins. Through the improvement of process technical, ShunTeh can flexibly increase the width and height to solve the heat sink fin is too wide and too thick problem. Provide customers with a wider selection of heat sinks. Applicable industries such as: UPS uninterruptible poShunTehr system, elevator equipment, large-scale inverter equipment, all kinds of large-scale equipment, etc., can be processed according to customer's drawing design, good heat dissipation effect, bringing new style to traditional heat sink change.

Aluminum Laminated Heat Sink-Inverter use

For special industries, Shun Teh can break through the traditional heat sink width limit without the additional mold cost of aluminum extrusion. Base on the aluminum extrusion and the patented method and the special aluminum extrusion structure to combined with large and large size heat dissipation fins. Widely praised by the large equipment industry. Application industries such as, train equipment, large transformer equipment, large-scale substation equipment, large-scale inverter equipment.

Stir Welding Heat Sink

Stir ShunTehlding heat sink break through the traditional heat sink width limited without the additional mold cost of aluminum extrusion. Base on the aluminum extrusion with special ShunTehlding process and high-strength bonding force for aluminum alloy workpieces, the thermal conductivity has not changed much. By patented method combined with large and large size heat dissipation fins.