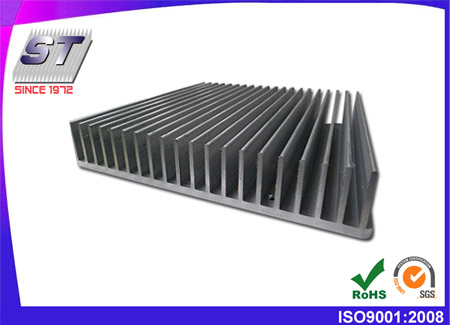

Aluminum Laminated Heat Sink- for electronic industries

For special industries, Shun Teh can break through the traditional heat sink width limit without the additional mold cost of aluminum extrusion. Base on the aluminum extrusion and the patented method and the special aluminum extrusion structure to combined with large and large size heat dissipation fins. Widely praised by the large equipment industry. Application industries such as, train equipment, large transformer equipment, large-scale substation equipment, large-scale inverter equipment.

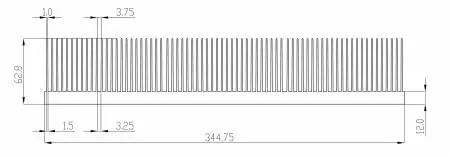

Heat sink for air conditioning industry 465.0mm×113.0mm

AA07

Base on traditional extrusion, ShunTeh combine special structures to create a brand new and big size heat sink. Especially for big equipments, ShunTeh got many good responses from customers by improving their thermal solution.

Heat sink for electrical industry 465.0mm×113.0mm

AA08

ShunTeh can customize heat sink according to customer's request. No need to make a new mold, ShunTeh can combine standard products to a bigger heat sink, include all surface machining and finish.