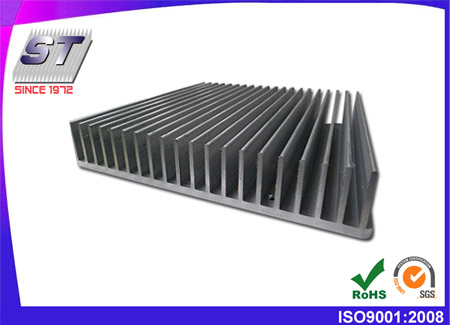

Heat sink for telecom and datacom industry 52.5mm×32.4mm

A220

It's special shape heat sink, ShunTeh drilled holes from fin side and flat side. Also, it can be applied to uninterruptible poShunTehr system.

heat sink for UPS

Material

- Aluminum alloy 6063-T5

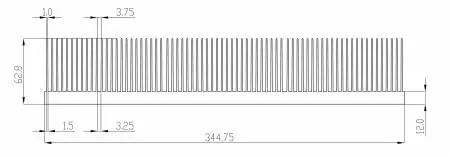

Dimension

- Heat Sink Width 52.5mm/2.06inch

- Heat Sink Height 32.4mm/1.27inch

- Heat Sink can be cut by any length. (*We can customize it according to your request.)

Manufacturing Equipment

- Cutting Machine

- CNC Machine

- Punching Machine

- Deburring and Grinding Machines

- Ultrasonic Cleaning Machine

- Drill Hole and Tap Machines

Finish

- Color Anodizing, Plating, Chromate, Painting, Blasting (* We can customize it according to your request.)

Package

- Carton or pallet (* We can customize it according to your request.)

Application

- Used for various electronic industries, ex: LED, Computer, UPS, Variable-frequency Drive, VFD, AC inverter...etc.

- Especially for big equipments, ex: train and elevator...etc.

- Other Information

- Lead Time: Depending on product procedure

- OEM Service: Yes

- Certification

- RoHS 2.0

- SGS

- ISO 9001:2015

- Files Download

.jpg?v=7f8651e2)